Build a Rock-Solid Metal Shed Foundation That Won’t Sink or Shift

A proper foundation determines the longevity and stability of your metal storage shed. Choose from several best foundation options, including concrete slabs, gravel pads, or concrete blocks, based on your terrain and local climate. Level the installation site with a slope of 1 inch per 8 feet for optimal drainage, preventing water accumulation and rust formation. Create a perimeter 12 inches wider than your shed’s dimensions to ensure adequate support and stability across the entire structure. Compact the soil thoroughly before laying your chosen foundation material, achieving a 95% compaction rate to prevent future settling and structural issues. This critical groundwork transforms your metal shed from a simple storage solution into a lasting, maintenance-free investment that protects your belongings while maintaining your property’s value.

Why Your Metal Shed Foundation Really Matters

Weight Distribution Requirements

Metal sheds require careful weight distribution to maintain their structural integrity and prevent long-term issues. The typical metal shed distributes its weight along the perimeter walls and through key support points in the floor frame. Without proper support, the shed can develop sagging floors, warped walls, or even complete structural failure.

A metal shed’s weight isn’t just about the structure itself – you need to consider everything you’ll store inside. Garden tools, lawn equipment, and seasonal items can add significant weight that needs even distribution across the foundation. Most residential metal sheds require a foundation that can support 20-30 pounds per square foot of floor space.

For optimal weight distribution, ensure your foundation extends slightly beyond the shed’s footprint and remains perfectly level. This prevents edge stress and maintains even support across the entire structure. Installing additional support beams or concrete piers at high-stress points, particularly where heavy items will be stored, can provide extra stability and prevent future problems.

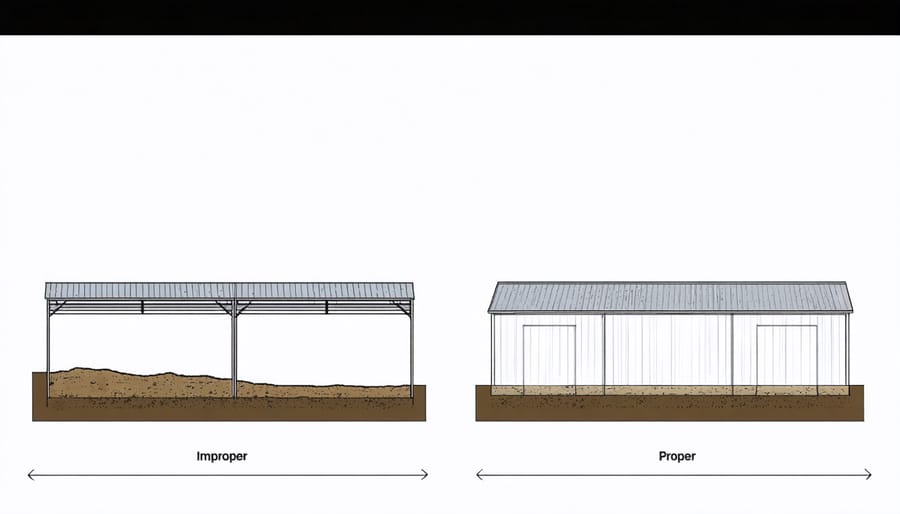

Moisture and Rust Prevention

Proper foundation selection plays a crucial role in helping to extend your metal shed’s lifespan by preventing moisture-related issues and rust. A well-designed foundation creates a barrier between your shed’s metal components and ground moisture, which is one of the primary causes of premature rusting. Elevated foundations, like concrete slabs or gravel beds, provide excellent drainage and airflow underneath the structure, keeping the base dry even during wet seasons.

To maximize moisture protection, ensure your foundation slopes slightly away from the shed, allowing water to drain naturally. Installing a vapor barrier beneath gravel or concrete foundations adds an extra layer of protection. Consider adding rubber or plastic shims between the foundation and shed base to create a moisture-break and prevent direct contact with potentially damp surfaces.

Regular inspection of the foundation-to-shed connection points helps catch any moisture issues early, protecting your investment for years to come.

Best Foundation Options for Metal Storage Sheds

Concrete Slab Foundations

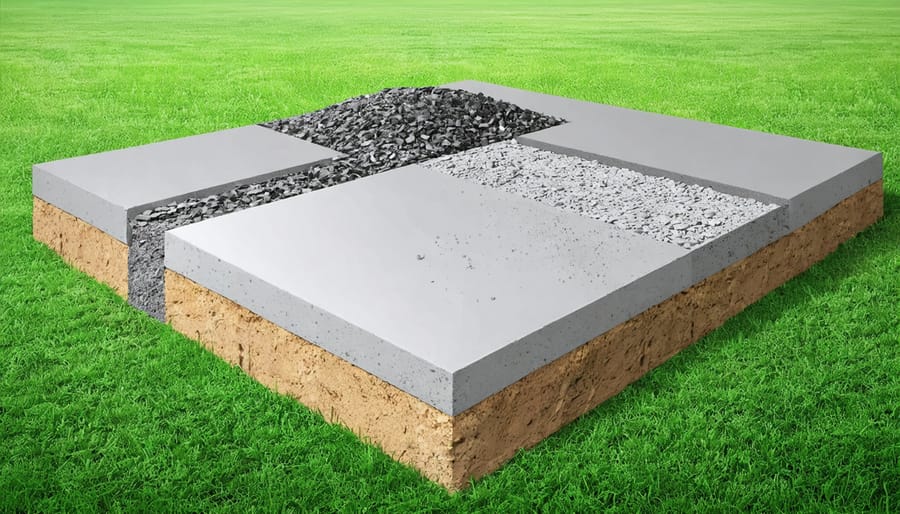

A concrete slab foundation offers the most durable and stable base for your metal storage shed. This permanent solution consists of a solid, reinforced concrete pad that provides excellent support and protection against moisture and pests. While it requires more initial investment and effort, a properly installed concrete slab can last for decades with minimal maintenance.

To create a concrete slab foundation, start by excavating the area to a depth of about 4-6 inches, ensuring the ground is level and compacted. Add a layer of gravel for drainage, followed by a vapor barrier to prevent moisture from seeping up through the concrete. Install reinforcement mesh or rebar before pouring the concrete to prevent cracking and increase structural integrity.

The concrete should be at least 4 inches thick and slightly slope away from the center for proper drainage. Consider adding a thickened edge around the perimeter for additional strength. Allow the slab to cure completely before installing your shed, which typically takes about a week.

Benefits of a concrete slab include:

– Superior stability and longevity

– Perfect for larger sheds and heavy equipment storage

– Excellent moisture protection

– Level surface that won’t settle over time

– Easy maintenance and cleaning

– Built-in rodent protection

Remember to check local building codes, as some areas require permits for concrete foundations.

Gravel Pad Foundations

A gravel pad foundation offers an excellent balance of durability, drainage, and cost-effectiveness for metal storage sheds. To create one, start by excavating the area to a depth of 4-6 inches, making sure to extend about 12 inches beyond your shed’s dimensions. Line the excavated area with landscape fabric to prevent weed growth and maintain the gravel’s stability.

Fill the area with crushed stone or gravel, starting with larger stones (¾ inch) at the bottom and working up to finer gravel on top. Compact each layer thoroughly using a plate compactor to ensure a solid base. The finished surface should be perfectly level and slightly elevated from the surrounding ground to promote proper drainage.

One of the biggest advantages of gravel foundations is their excellent drainage capability, which helps prevent water damage to your shed’s metal components. They’re also relatively easy to install as a DIY project and can be adjusted or releveled if needed. Many homeowners appreciate that gravel foundations allow for natural ground settling while maintaining structural integrity.

For best results, choose angular gravel rather than round river rock, as it locks together better and provides superior stability. Remember to check local building codes, as some areas may have specific requirements for shed foundations.

Concrete Block Foundations

Concrete blocks offer a sturdy and cost-effective foundation solution for your metal storage shed. Start by laying out your blocks in a grid pattern, ensuring they’re spaced evenly according to your shed’s dimensions. A typical arrangement places blocks every 4-6 feet along the perimeter and interior support points.

Before positioning your blocks, remove grass and topsoil, then add a 2-inch layer of gravel or crushed stone to promote drainage. Use a laser level or string level to ensure each block sits at the same height – this is crucial for preventing future structural issues. For additional stability, consider placing solid concrete cap blocks on top of hollow blocks.

When working with sloped terrain, you may need to dig deeper on the high side or stack blocks to achieve a level surface. Remember to check your layout with diagonal measurements to confirm the foundation is square. For areas with frost concerns, dig below the frost line and place blocks on concrete footings for extra stability.

Pro tip: Use pressure-treated lumber between the blocks and shed frame to prevent metal-on-concrete contact and reduce moisture transfer.

Site Preparation Steps

Ground Leveling

Creating a level surface for your metal storage shed is crucial for its long-term stability and functionality. Start by clearing the area of all vegetation, rocks, and debris. Using a string level and stakes, mark the perimeter of your intended foundation area, extending about 12 inches beyond your shed’s dimensions on all sides.

Following proper ground leveling techniques is essential for preventing future settling issues. Use a long level or transit level to identify high spots and low areas. Remove soil from elevated areas rather than filling in low spots, as added soil can settle over time. For slight elevation differences, a steel rake can help distribute the soil evenly.

Once roughly leveled, compact the soil using a plate compactor, working in a systematic pattern across the entire area. Check the level frequently during this process. For optimal results, spray a light mist of water over the soil before compacting – this helps achieve better compression. After compaction, verify that no point in your foundation area differs by more than ¼ inch in height from any other point. This careful preparation ensures your metal shed will sit perfectly level and remain stable for years to come.

Drainage Considerations

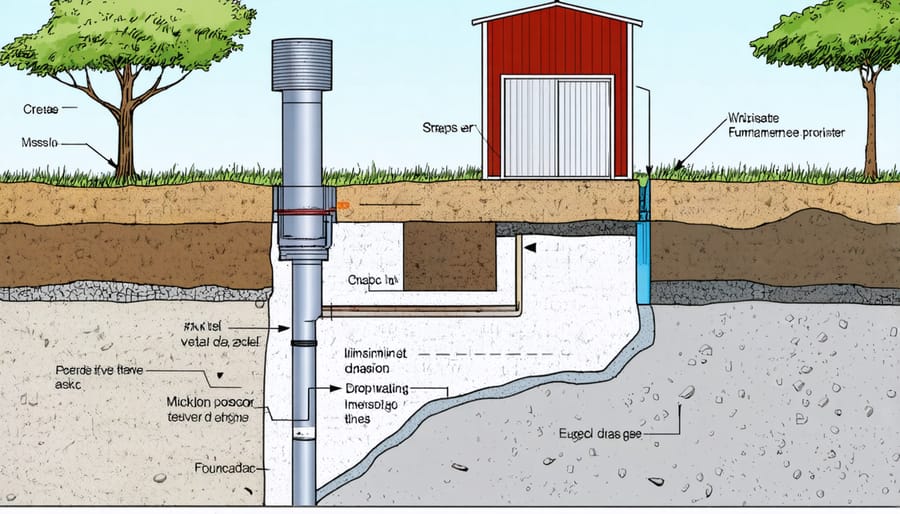

Proper drainage is crucial for protecting your metal shed and its contents from water damage. Start by ensuring your foundation site slopes away from the shed at a minimum grade of 1 inch per 8 feet. This gentle slope will direct water away from your structure naturally.

Consider installing a perimeter drain around your foundation, particularly if you live in an area with heavy rainfall. A layer of crushed stone or gravel beneath your foundation will create excellent drainage and prevent water from pooling underneath your shed. Aim for a 4-inch deep layer of 3/4-inch crushed stone.

Don’t forget to plan for roof runoff. Install gutters and downspouts to channel rainwater away from your foundation. Direct downspouts at least 3 feet away from the shed, using extension pipes if necessary. In areas with poor natural drainage, consider creating a French drain system to carry water to a more suitable location.

Remember to regularly check that your drainage systems remain clear of debris and functioning properly, especially during rainy seasons. This simple maintenance can prevent costly water damage down the line.

Common Foundation Mistakes to Avoid

When installing a metal storage shed foundation, avoiding common mistakes can save you time, money, and future headaches. One of the most frequent errors is rushing through site preparation. Take time to remove all vegetation, rocks, and debris from the area, as these can cause shifting and uneven settling over time.

Many DIY enthusiasts underestimate the importance of proper leveling. Even a slight slope can lead to doors that won’t close properly and walls that twist. Always use a laser level or transit level for accuracy, and double-check your measurements before proceeding.

Another critical mistake is choosing the wrong foundation size. Your foundation should extend at least 2-4 inches beyond your shed’s dimensions on all sides. This overhang helps protect the shed’s base from water damage and provides better stability.

Poor drainage planning can spell disaster for your shed foundation. Ensure the site has a slight grade away from the foundation, and consider installing a French drain if your area experiences heavy rainfall. Some homeowners skip installing a vapor barrier, which can lead to moisture problems and premature deterioration of both the foundation and shed.

Using substandard materials to save money often proves costly in the long run. Opt for high-quality concrete, gravel, and other materials that meet local building codes. Also, avoid mixing concrete on days with extreme temperatures, as this can affect curing and strength.

Remember to check local building codes before starting. Many homeowners skip this step and face fines or mandatory modifications later. Finally, don’t rush the curing process if using concrete – allow proper drying time as recommended by the manufacturer.

A solid foundation is the cornerstone of a successful metal shed installation, and choosing the right one can significantly impact your storage solution’s longevity and performance. As we’ve explored, whether you opt for a concrete slab, gravel bed, or block foundation, proper preparation and installation are crucial for ensuring stability and durability. The benefits of metal sheds are best realized when they’re built on a foundation that’s level, well-drained, and appropriate for your specific site conditions.

Remember to always check local building codes, assess your soil type, and consider your climate before making a final decision. While the upfront investment in a quality foundation might seem substantial, it’s far more cost-effective than dealing with structural issues later. Take time to properly prepare your site, ensure adequate drainage, and don’t hesitate to consult professionals if you’re unsure about any aspect of the foundation installation.

By following the guidelines we’ve discussed and maintaining your foundation regularly, you’ll create a stable, long-lasting base for your metal storage shed that will serve you well for years to come.