Make Your Shed Last Forever: Weatherproof 2x4s That Won’t Rot or Warp

Transform your outdoor construction project with premium weather-resistant materials like pressure-treated 2×4 lumber, engineered specifically to withstand nature’s harshest elements. Modern weatherproof 2x4s combine advanced chemical treatments with innovative manufacturing processes to deliver exceptional durability and dimensional stability, making them ideal for shed construction, outdoor framing, and exposed structural applications. These specially treated timbers resist rot, decay, and insect infestation while maintaining their structural integrity through seasonal changes – a critical advantage over standard lumber that can warp and deteriorate when exposed to moisture. Whether you’re building a new storage shed or upgrading existing outdoor structures, choosing the right weatherproof lumber ensures your investment stands strong against rain, snow, and sun for decades to come.

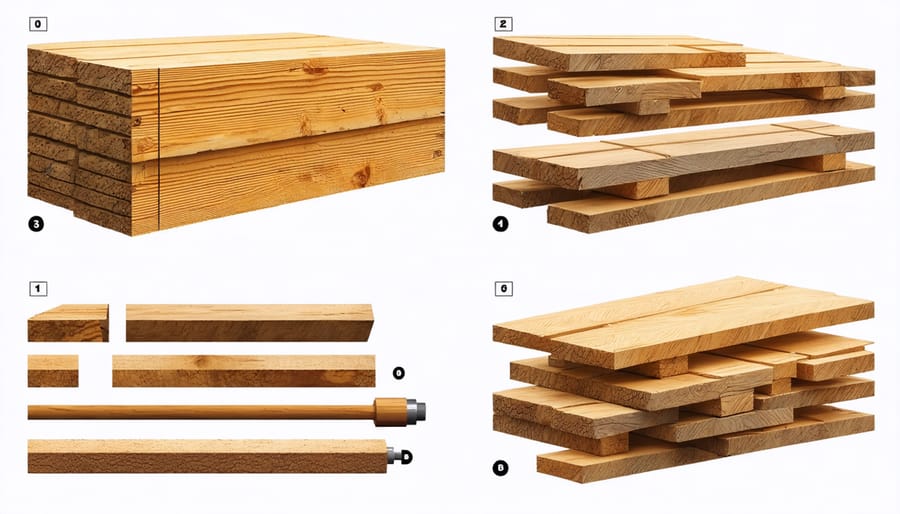

What Makes a 2×4 Truly Weatherproof?

Pressure-Treated vs. Regular Lumber

When it comes to choosing lumber for your shed, understanding the difference between pressure-treated and regular lumber is crucial. Pressure-treated lumber undergoes a special process where protective chemicals are forced deep into the wood, making it highly resistant to rot, insects, and fungal growth. This treatment significantly extends the wood’s lifespan, especially when it comes in contact with moisture or ground.

Regular lumber, while more affordable upfront, doesn’t offer the same level of protection against the elements. Without treatment, it’s more susceptible to water damage, decay, and pest infestation. However, regular lumber can still be suitable for above-ground applications when properly sealed and maintained.

For areas where wood directly contacts the ground or is exposed to frequent moisture, pressure-treated lumber is the clear winner. It’s particularly important for foundation components, bottom plates, and any parts of your shed that might be exposed to water splash or ground contact. While pressure-treated lumber costs about 30-40% more than regular lumber, the long-term durability and reduced maintenance needs often make it a worthwhile investment for outdoor structures.

Understanding Pressure Treatment Grades

Pressure-treated lumber comes in different grades, each designed for specific exposure levels and uses. The most common grades you’ll encounter are Above Ground (UC3B), Ground Contact (UC4A), and Heavy-Duty Ground Contact (UC4B). For shed construction, Above Ground treatment is suitable for most wall studs and roof supports that don’t directly touch soil or concrete. However, any 2x4s that will be within 6 inches of the ground should be rated for Ground Contact.

The treatment level is typically indicated by a stamp or tag on the lumber. Look for a light green or olive color, which shows the wood has been properly treated. Above Ground lumber contains about 0.25 pounds of preservative per cubic foot, while Ground Contact material contains 0.40 pounds or more.

For areas with high moisture or frequent rain, opt for Ground Contact grade even for above-ground applications. This provides extra protection and longer life, especially in coastal regions or spots with poor air circulation. Remember that higher treatment levels can be used in place of lower ones, but never the other way around.

Best Weatherproof 2×4 Options for Your Shed

Ground Contact Rated Lumber

Ground contact rated lumber offers exceptional protection against moisture, decay, and insect infestation, making it an ideal choice for shed construction where wood comes in direct contact with the ground. This specially treated lumber undergoes a more intensive preservation process than standard pressure-treated wood, resulting in higher chemical retention levels that provide superior protection.

When building your shed, using ground contact rated lumber for the base frame and floor joists is crucial, especially in areas where proper foundation installation might be challenging. These materials are designed to withstand constant exposure to moisture, soil, and harsh weather conditions, ensuring your shed’s structural integrity for years to come.

Look for lumber marked with “Ground Contact” or “GC” on the end tag, along with preservation levels of .40 pcf (pounds per cubic foot) or higher. This rating indicates the wood has received adequate treatment to resist decay and insect damage even in challenging conditions.

While ground contact rated lumber may cost slightly more than standard pressure-treated wood, the investment pays off through extended durability and reduced maintenance needs. For shed applications, focus on using this material for bottom plates, support beams, and any components that will be within 18 inches of the ground.

Above Ground Treated Lumber

Above-ground treated lumber is specifically designed for applications where wood isn’t in direct contact with soil but still needs protection from moisture and weather elements. This type of lumber undergoes a specialized treatment process that makes it resistant to rot, decay, and insect infestation while being safe for residential use.

When selecting above-ground treated lumber for your shed, look for pieces marked with “ABOVE GROUND USE” or “AG” on the end tag. These 2x4s typically have a lighter green tint compared to ground-contact lumber and are perfect for wall studs, roof rafters, and other elevated components of your shed structure.

The treatment level in above-ground lumber is ideal for areas that can dry quickly after rain and aren’t constantly exposed to moisture. It’s particularly well-suited for:

– Wall framing

– Roof trusses

– Door and window frames

– Interior support beams

– Elevated decking components

While more affordable than ground-contact treated lumber, above-ground treated 2x4s still offer excellent weather resistance when properly installed and maintained. To maximize their lifespan, ensure proper ventilation in your shed design and maintain at least 6 inches of clearance between the lumber and ground level.

For best results, seal any cut ends with a preservative treatment and use proper fasteners rated for treated lumber to prevent corrosion issues.

Additional Protection Methods

Sealants and Coatings

Even with pressure-treated lumber, applying additional sealants and coatings can significantly enhance your 2×4’s weather resistance and extend its lifespan. To effectively protect against rain and rot, consider using a high-quality water-repellent sealer or wood preservative.

Oil-based sealants provide excellent protection by penetrating deep into the wood fibers, creating a robust barrier against moisture. Water-based options are also effective and typically easier to apply, with the added benefit of faster drying times. For optimal results, apply two coats, allowing proper drying time between applications.

Paint is another reliable option, offering both protection and aesthetic appeal. Choose exterior-grade paint specifically designed for treated lumber, and don’t forget to prime the wood first. Some homeowners prefer transparent or semi-transparent stains that protect while showcasing the wood’s natural grain.

Remember to reapply your chosen protective coating every 2-3 years, depending on your climate and the product used. Pay special attention to end grain areas and joints, as these spots are particularly vulnerable to moisture absorption. Regular maintenance of your protective coating will ensure your 2x4s remain sturdy and weatherproof for years to come.

Proper Installation Techniques

When installing weatherproof 2x4s, proper technique is crucial for long-lasting results. Start by storing your lumber in a covered area for 48-72 hours before installation, allowing it to acclimate to local conditions. This helps prevent warping and twisting after installation.

Always use stainless steel or hot-dipped galvanized fasteners to prevent rust and ensure a secure hold. Space your fasteners about 16 inches apart and at least 3/4 inch from the board’s edge to prevent splitting. Pre-drill holes when working near the ends of boards to minimize cracking.

For ground contact, always place a moisture barrier between the soil and lumber, even with treated wood. Use concrete blocks or post anchors to elevate the wood slightly off the ground. When joining pieces, create angled cuts for water runoff and apply a waterproof sealant to all cut ends.

If you’re installing horizontal boards, maintain a slight slope (about 1/4 inch per foot) to encourage water drainage. For vertical installations, ensure the bottom ends are properly sealed and elevated. Remember to leave small gaps between boards for expansion and contraction with seasonal changes – about 1/8 inch is typically sufficient.

Maintenance Tips for Long-Term Protection

Regular maintenance is key to extending the life of your weatherproof 2x4s and protecting your investment. Start by conducting seasonal inspections, particularly after severe weather events, to catch any potential issues early. Look for signs of water damage, splitting, or any areas where the protective coating might be wearing thin.

Keep your lumber clean by gently washing it with a mild soap solution and soft brush at least twice a year. This removes dirt, mold, and debris that could compromise the wood’s protective barriers. After cleaning, ensure the wood dries completely before applying any new treatments.

Apply a fresh coat of weatherproof sealant every 2-3 years, or sooner if you notice the existing coating starting to wear. Before application, lightly sand any rough spots and clean the surface thoroughly. Choose a day with moderate temperature and low humidity for best results.

Pay special attention to end grain areas, as these are particularly vulnerable to moisture absorption. Apply extra sealant to these spots and consider using end caps for additional protection. Also, maintain proper ventilation around your lumber by keeping it elevated off the ground and ensuring adequate air circulation.

Address any damage promptly to prevent further deterioration. Small cracks or splits can be filled with appropriate wood filler, while more severe damage might require board replacement. Remember that prevention is always easier than repair, so regular maintenance checks are your best defense against weather-related damage.

Choosing the right weatherproof 2×4 lumber for your shed project is crucial for long-term durability and protection. By selecting pressure-treated lumber, implementing proper weather barriers, and maintaining regular inspections, you can ensure your shed stands strong against the elements for years to come. Remember to always store your lumber properly before construction, apply additional protective treatments as needed, and address any signs of weather damage promptly. Whether you opt for pressure-treated pine, cedar, or composite materials, the key is matching your choice to your local climate conditions and maintenance preferences. With these guidelines in mind, you’re well-equipped to build a weather-resistant shed that provides reliable storage while maintaining its structural integrity through all seasons.