UV-Stabilized Greenhouse Plastic: The Smart Shield for Your Storage Shed

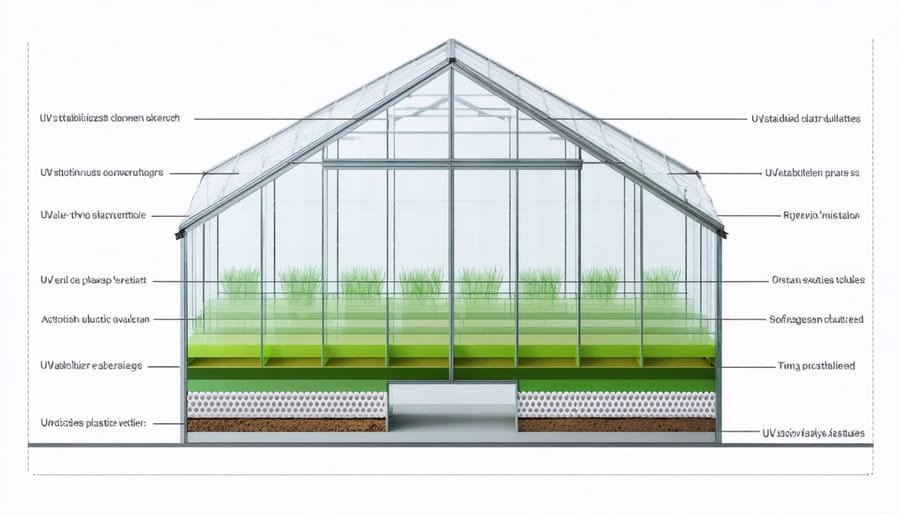

UV stabilized greenhouse plastic revolutionizes how we protect our storage structures and extend growing seasons. This specialized polyethylene film blocks harmful UV rays while maintaining optimal light transmission, offering up to four times the lifespan of standard greenhouse covers. Unlike traditional plastics that become brittle and discolor within months, UV stabilized covers maintain their structural integrity for 3-4 growing seasons, making them a cost-effective solution for both commercial growers and home gardeners. The material’s advanced UV inhibitors prevent degradation from intense sunlight, while its thermal properties create an ideal microclimate for plant growth by retaining heat during cold nights and diffusing harsh sunlight during peak hours. For gardeners seeking reliable, long-term protection for their greenhouses, UV stabilized plastic delivers professional-grade performance without the premium price tag of glass or polycarbonate panels.\n\n\n

Why UV Protection Matters for Your Shed

\n\n

Common UV Damage Signs

\n\nRecognizing UV damage on shed materials early can help you address issues before they become serious problems. The most noticeable sign is color fading or yellowing of your greenhouse plastic, which indicates the material is breaking down. You might also notice the plastic becoming increasingly brittle or developing small cracks, particularly around edges and corners. Another telltale sign is a chalky or powdery residue on the surface, which occurs when UV rays break down the material’s surface layer. Watch for areas that become increasingly cloudy or opaque, as this reduces light transmission and affects plant growth. If you can gently flex the plastic and hear crackling sounds, this suggests the material has become brittle and may need replacement. Regular inspections of these warning signs can help you maintain your greenhouse’s protective covering and extend its lifespan.\n\n

\n

\n\n\n

The Cost of Ignoring UV Protection

\n\nIgnoring UV protection for your greenhouse plastic can lead to significant financial consequences over time. Without proper UV stabilization, standard plastic coverings typically deteriorate within a single growing season, requiring frequent replacements that can cost hundreds of dollars annually. These recurring expenses quickly add up, often surpassing the initial investment of quality UV-stabilized materials by the second or third year.\n\nBeyond the direct replacement costs, UV damage can lead to poor temperature regulation and reduced light transmission, potentially affecting plant growth and crop yields. This can result in lower produce quality and quantity, directly impacting your garden’s productivity. Additionally, deteriorating plastic may tear unexpectedly during adverse weather conditions, potentially causing damage to valuable plants and equipment inside your greenhouse.\n\nWhen you factor in the labor time for repeated installations and the potential loss of growing opportunities, choosing non-UV stabilized materials can cost three to four times more over a five-year period.\n\n\n

UV-Stabilized Greenhouse Plastic: Your Shed’s Shield

\n\n

What Makes It Different

\n\nUV stabilized greenhouse plastic stands apart from standard plastic coverings thanks to special additives that protect against the sun’s harmful rays. These additives work like a built-in sunscreen, absorbing UV radiation before it can break down the plastic’s molecular structure. This means your greenhouse covering won’t become brittle, yellow, or crack prematurely.\n\nWhat makes this technology truly remarkable is its longevity-enhancing properties. While regular plastic might deteriorate within a single growing season, UV stabilized versions can last 3-4 times longer. The stabilizers are mixed directly into the plastic during manufacturing, ensuring even protection throughout the material rather than just on the surface.\n\nThe stabilization process also helps maintain light transmission quality over time. Regular plastic can become cloudy and less transparent as it ages, but UV stabilized versions maintain their clarity much longer. This means your plants continue receiving the optimal amount of light they need to thrive.\n\nThese materials are also engineered to withstand temperature fluctuations without warping or shrinking. The UV stabilizers help maintain the plastic’s flexibility, making it less likely to tear during seasonal changes or strong winds. For greenhouse owners, this translates to fewer replacements, better climate control, and more consistent growing conditions throughout the year.\n\n

\n

\n\n\n

Durability and Lifespan

\n\nUV stabilized greenhouse plastic is designed to withstand the harsh effects of sunlight, typically lasting between 3 to 5 years when properly installed and maintained. This specialized material works alongside other methods to make your shed last longer by providing reliable protection against UV radiation.\n\nThe durability of UV stabilized plastic depends on several factors, including thickness and quality. Premium 6-mil sheets often outperform thinner alternatives, maintaining their clarity and structural integrity for the full expected lifespan. In optimal conditions, some high-quality products can even extend beyond the 5-year mark, though it’s best to plan for replacement within the manufacturer’s recommended timeframe.\n\nTo maximize longevity, look for products with a warranty of at least 4 years, which indicates the manufacturer’s confidence in their UV stabilization technology. The plastic should maintain at least 90% of its light transmission capabilities throughout its service life, ensuring your greenhouse or shed remains properly illuminated.\n\nRegular inspection is key to monitoring the plastic’s condition. Watch for signs of yellowing, brittleness, or cracking, which indicate it’s time for replacement. Many gardeners and shed owners report that investing in quality UV stabilized plastic upfront results in fewer replacements and better protection over time.\n\n\n

Installation Tips for Maximum Protection

\n\n

Tools and Materials

\n\nTo properly install UV stabilized greenhouse plastic, you’ll need these essential tools and materials:\n\nEssential Tools:\n- Measuring tape\n- Sharp utility knife or scissors\n- Staple gun with 3/8-inch staples\n- Drill with screwdriver bits\n- Wooden batten strips\n- Anti-hot spot tape\n- Work gloves\n- Safety glasses\n\nMain Materials:\n- UV stabilized greenhouse plastic (calculate square footage plus 20% extra)\n- Wiggle wire and aluminum channel (for secure fastening)\n- Weather-resistant screws\n- Poly repair tape\n- Spring clips or snap clamps\n\nOptional but Recommended:\n- Helper springs for tension control\n- Foam weather stripping\n- Double-sided greenhouse tape\n- Plastic repair patches\n- Cleaning supplies (soft cloth and mild soap)\n\nPro Tip: Always buy slightly more plastic than your measurements indicate to account for overlaps and potential mistakes. Store unused materials in a cool, dry place for future repairs.\n\nRemember to check all tools are in good working condition before starting your installation project. Having everything ready beforehand will make the process smoother and more efficient.\n\n

\n

\n\n\n

Step-by-Step Application

\n\nInstalling UV stabilized greenhouse plastic requires careful attention to ensure proper coverage and longevity. Begin by measuring your greenhouse frame accurately, adding an extra 6 inches on each side for secure fastening. Clean the frame thoroughly to remove any dirt or debris that could damage the plastic.\n\nChoose a calm, warm day for installation, as the plastic will be more pliable and easier to work with. Start at one end of the greenhouse, securing the plastic with snap-on channels or batten tape. Work your way down the structure, pulling the plastic taut but not overstretching it.\n\nFor the sides, begin at the top and work downward, maintaining even tension throughout. Use appropriate greenhouse clips or fasteners every 16-24 inches along the frame. Create small pleats at corners to prevent wrinkles and ensure smooth coverage.\n\nFinally, trim excess material carefully, leaving enough for secure anchoring at the base. Consider adding anti-hotspot tape to metal frame contact points to prevent heat damage. Double-check all fasteners and ensure proper tension to prevent wind damage or sagging.\n\n\n

Maintenance and Care

\n\nProper maintenance of your UV stabilized greenhouse plastic is essential for maximizing its lifespan and effectiveness. Start by regularly cleaning the surface with a soft brush and mild soap solution to remove dirt, debris, and organic matter that can trap moisture and promote degradation. Avoid using harsh chemical cleaners or abrasive materials that might scratch or damage the protective UV coating.\n\nInspect your greenhouse plastic covering at least twice a year for any signs of wear, tears, or areas where the material might be stretching. Pay special attention to areas around fasteners and corners where stress points commonly occur. If you notice any small tears, repair them promptly using UV-resistant repair tape to prevent further damage.\n\nTo maintain optimal UV protection, avoid letting the plastic come into contact with wooden surfaces treated with preservatives, as these chemicals can react with the UV stabilizers. When working near the greenhouse, keep sharp tools and equipment away from the plastic to prevent accidental punctures.\n\nDuring winter months, remove any snow accumulation promptly to prevent excessive weight strain. If you’re in an area with strong winds, check and adjust the tension of your plastic covering regularly to prevent flapping and unnecessary wear.\n\nConsider applying a shade compound during peak summer months to provide additional UV protection and regulate internal temperatures. Remember that while UV stabilized plastic is designed for durability, its effectiveness gradually decreases over time. Plan to replace your greenhouse covering according to the manufacturer’s recommended lifespan, typically every 4-6 years, to maintain optimal protection.\n\n\nInvesting in UV stabilized greenhouse plastic is a smart choice for protecting your valuable storage space and extending the life of your shed or greenhouse structure. By understanding the key benefits – including enhanced durability, superior UV protection, and cost-effectiveness – you can make an informed decision about protecting your investment. Remember that proper installation and regular maintenance are essential for maximizing the effectiveness of your UV stabilized covering.\n\nWhether you’re a seasoned DIY enthusiast or a homeowner looking to protect your storage space, UV stabilized greenhouse plastic offers a practical and reliable solution. By following the installation guidelines and maintenance tips we’ve discussed, you can ensure your covering performs optimally for years to come.\n\nDon’t wait until sun damage affects your shed or greenhouse – take action now to protect your structure and its contents. With the right UV stabilized plastic and proper care, you can enjoy a durable, protected space that maintains its integrity through all seasons. Start planning your installation today and give your storage space the protection it deserves.