Stop Wasting Money on Your Shed’s Hidden Energy Drain

Check your monthly electricity bill and compare usage before and after installing a power monitoring system in your shed—most homeowners discover they’re wasting 20-30% more energy than expected on forgotten space heaters, inefficient lighting, or tools left plugged in overnight. Install a real-time monitoring device at your shed’s main electrical panel to track exactly which circuits and devices consume the most power, giving you instant visibility into where your money disappears each month. Set up automated alerts when consumption spikes unexpectedly, catching issues like a malfunctioning appliance or a door left open with heating running before your next bill arrives.\n\nPower monitoring systems transform your shed electrical systems from a mystery expense into a controllable, optimized part of your home energy strategy. These affordable devices connect directly to your existing electrical setup and provide detailed breakdowns through smartphone apps, showing you hourly, daily, and monthly consumption patterns without requiring an electrician’s expertise. Whether you’ve converted your shed into a workshop, home office, or hobby space, understanding your actual power usage helps you make smarter decisions about when to run equipment, which upgrades deliver real savings, and how to trim unnecessary costs without sacrificing comfort or functionality.\n\n\n

Why Your Shed’s Electrical System Needs Monitoring

\n\n

\n

\n\n\n

Common Energy Vampires Hiding in Your Shed

\n\nYou might be surprised by what’s quietly draining power in your shed, even when you think everything’s switched off. Old refrigerators or freezers used for storing beverages and garden produce are notorious energy guzzlers, especially if they’re running 24/7 in an uninsulated space where they work overtime during summer heat.\n\nBattery chargers left plugged in are another common culprit. Whether it’s for power tools, lawn equipment, or that rarely-used leaf blower, these chargers draw phantom power even when nothing’s charging. The same goes for electric heaters that homeowners leave on standby mode to prevent winter freeze damage.\n\nFluorescent shop lights with magnetic ballasts consume significantly more power than modern LED alternatives, particularly if you’re someone who forgets to flip the switch after finishing projects. Portable air compressors with automatic restart features can cycle on unnecessarily, and old dehumidifiers running constantly in damp spaces often use far more electricity than the problem warrants.\n\nEven outdoor security lights with faulty sensors can stay illuminated much longer than needed. The good news? Once you identify these energy vampires through monitoring, you can tackle them one by one with simple fixes like smart plugs, timers, or equipment upgrades that pay for themselves through reduced electricity bills.\n\n

What Unmonitored Power Actually Costs You

\n\nWithout monitoring, it’s surprisingly easy for your shed to quietly drain your wallet. Let’s look at what this actually means in real dollars and cents.\n\nConsider a typical workshop shed with a space heater, power tools, and lighting. If you’re unknowingly leaving that 1,500-watt space heater running overnight just three times per week, you’re adding roughly $15-20 to your monthly electric bill. Over a year, that’s $180-240 literally heating the night air.\n\nSarah, a hobbyist woodworker from Oregon, discovered her “vampire loads” were costing $22 monthly. Her old refrigerator in the shed, combined with tools left plugged in, consumed power 24/7 even when not in use. After installing a basic monitoring system, she identified these energy vampires and reduced her shed’s electricity costs by 65 percent within the first month.\n\nAnother common scenario involves outdoor lighting on faulty timers or motion sensors. John from Texas found his shed’s security lights were staying on 14 hours daily instead of the intended 6 hours, doubling his expected lighting costs to $18 monthly.\n\nThese aren’t dramatic numbers individually, but they add up to $200-400 yearly for many shed owners, money that simple awareness and monitoring can help you reclaim.\n\n\n

What Power Monitoring Systems Actually Do

\n\n

\n

\n\n\n

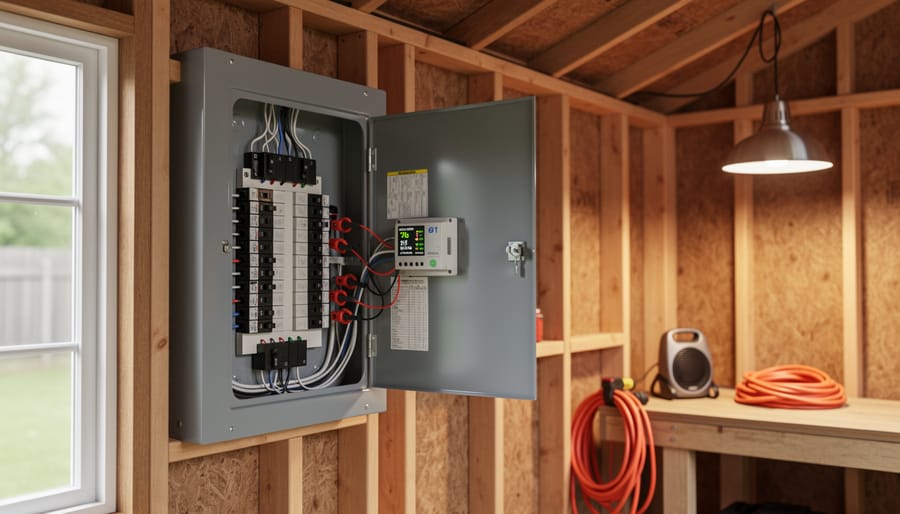

The Three Types of Power Monitors for Sheds

\n\nChoosing the right power monitor depends on how you use your shed and what you want to track. Let’s break down your three main options.\n\nPlug-in monitors are the simplest starting point. These affordable devices plug directly into your wall outlet, then you plug your tool or appliance into the monitor. They’re perfect if you’re curious about which specific equipment consumes the most power—maybe that old space heater or your workshop compressor. The downside? You can only monitor one device at a time, so they won’t give you a complete picture of your shed’s total energy use. They’re ideal for weekend DIYers who want to identify energy hogs without any installation hassle.\n\nCircuit-level monitors attach to individual circuits in your electrical panel. These give you a much clearer view of different areas of your shed—lighting separate from outlets, for example. Installation requires basic electrical knowledge or a quick call to an electrician, but once installed, they provide ongoing insights without the need to move anything around. This option works beautifully if your shed has multiple purposes, like a workshop zone and a storage area with climate control.\n\nWhole-shed systems monitor everything at once by connecting to your main electrical feed. They’re the most comprehensive solution, showing you exactly how much power your entire shed consumes in real-time. While they cost more upfront and typically need professional installation, they’re worthwhile if you’ve converted your shed into a home office, studio, or regularly use multiple power tools simultaneously.\n\n\n

Choosing the Right Power Monitor for Your Shed Setup

\n\n

For Basic Storage Sheds with Minimal Power Needs

\n\nIf your shed serves mainly as storage with just a light bulb and the occasional power tool charging station, you don’t need anything fancy. A simple plug-in energy monitor is your best friend here. These affordable devices sit between your wall outlet and whatever you’re powering, giving you real-time readings on a small display screen.\n\nThink of popular options like the Kill A Watt meter, which costs around $20-30 and requires zero installation expertise. Just plug it in, and you’ll instantly see how much energy your shed lighting uses each month. This straightforward approach helps many homeowners discover they’ve been leaving lights on unnecessarily or that switching to LED bulbs could save them a surprising amount annually.\n\nFor sheds with multiple outlets, consider a smart plug with energy monitoring features. These connect to your phone and send alerts if you’ve accidentally left something running, which is especially handy if your shed sits away from your main house.\n\n

For Workshop and Heavy-Use Sheds

\n\nIf you’re running a workshop or using multiple power-hungry tools and equipment, you’ll want a more robust monitoring setup. Panel-level monitors that track individual circuits give you the complete picture of where energy goes. These systems typically install inside your main electrical panel and use current transformers on each breaker, letting you see exactly which circuits draw the most power.\n\nThis detailed breakdown becomes invaluable when you’re running table saws, compressors, welders, and climate control simultaneously. One DIY enthusiast discovered his old space heater was consuming more electricity than all his power tools combined, prompting an upgrade that cut his shed’s winter costs by 40 percent.\n\nLook for systems offering real-time alerts when circuits exceed safe thresholds, helping prevent tripped breakers during critical projects. Many comprehensive monitors also track power quality, warning you about voltage fluctuations that could damage sensitive electronics or CNC equipment. The upfront investment typically pays for itself within a year through identifying energy waste and preventing costly equipment damage.\n\n

For She-Sheds, Greenhouses, and Climate-Controlled Spaces

\n\nShe-sheds, greenhouses, and hobby spaces with climate control need extra attention when it comes to power monitoring. These buildings often run heaters, air conditioners, dehumidifiers, or grow lights around the clock, making them some of the biggest energy consumers on your property. A power monitoring system helps you catch problems early—like a space heater drawing more power than expected or a thermostat stuck in heating mode overnight.\n\nLook for monitors that track multiple circuits separately so you can see exactly which appliance is using the most power. This is especially helpful in greenhouses where lighting and ventilation systems operate on different schedules. Consider smart electrical solutions that send alerts to your phone when energy use spikes unexpectedly—this could signal equipment failure before your plants suffer or your she-shed becomes uncomfortable. Many homeowners discover their biggest savings come from simply adjusting heating and cooling schedules based on actual usage data rather than guesswork.\n\n\n

Installing Your Power Monitoring System (The DIY-Friendly Way)

\n\n

\n

\n\n\n

What You’ll Need Before You Start

\n\nBefore diving into power monitoring, let’s make sure you have everything ready for a smooth setup. You won’t need a toolbox full of specialized equipment—most installations are surprisingly straightforward.\n\nFirst, ensure your shed’s electrical panel is accessible and you know where your circuit breaker is located. You’ll typically need a smartphone or tablet to connect with most modern monitoring systems, as they rely on apps for tracking your energy data.\n\nSafety is paramount when working around electricity. If you’re uncomfortable working near your electrical panel, there’s no shame in calling a licensed electrician. Many monitoring systems offer professional installation services for added peace of mind.\n\nFor basic installations, have a screwdriver set handy and consider wearing rubber-soled shoes. Always turn off power at the main breaker before making any connections. Keep your system’s installation manual nearby—these guides are written with homeowners in mind and walk you through each step clearly.\n\n

Safety First: When to Call a Professional

\n\nInstalling a basic power monitoring display that plugs into an existing outlet? That’s typically DIY-friendly territory. However, anything involving your shed’s main electrical panel, hardwiring devices, or making changes to your circuit breaker system requires expertise. If you’re uncomfortable working with electricity, notice sparking, smell burning, or encounter wiring that doesn’t match standard color codes, it’s time to call a professional. Licensed electricians ensure your monitoring system integrates safely with your shed’s power supply without creating fire hazards or code violations. Remember, your homeowner’s insurance may not cover DIY electrical work gone wrong. When in doubt, professional installation costs less than potential repairs or medical bills down the road.\n\n\n

Making Sense of Your Power Data

\n\n

Simple Changes That Cut Your Shed’s Power Bill

\n\nOnce your monitoring system reveals where power is going, you can make targeted changes that really add up. Many shed owners discover their old incandescent bulbs are the biggest culprits—switching to LED upgrades typically cuts lighting costs by 75% or more and is the fastest payback of any improvement.\n\nTimer switches are another game-changer. Install them on heaters, fans, or lighting circuits so equipment only runs when needed. One homeowner reduced their workshop heating costs by 40% simply by adding a timer that prevented the space heater from running overnight.\n\nDon’t overlook insulation improvements either. Monitoring data showing constant heater usage often points to poor insulation letting warmth escape. Adding weatherstripping around doors or insulating walls keeps your shed comfortable while using less power.\n\nFinally, use your monitoring dashboard to identify habit changes. If data shows your power tools draw standby power when plugged in, create a routine of unplugging them after use. Small behavioral shifts, guided by real numbers from your system, create lasting savings without sacrificing convenience.\n\n\n

Real Shed Owners Share Their Savings Stories

\n\nMeet Sarah from Oregon, who transformed her workshop shed into an energy-efficient space after installing a basic power monitoring system. “I had no idea my old space heater was running up my bill so much,” she shares. “Within the first week of monitoring, I realized it was drawing power constantly, even when I thought it was in low mode.” By switching to a more efficient heating solution and unplugging tools when not in use, Sarah cut her shed’s energy costs by 40 percent in just three months.\n\nThen there’s Mike, a weekend woodworker in Michigan, who was shocked to discover his dust collection system was the culprit behind his high summer bills. “I installed a simple plug-in monitor on my major tools and found that my dust collector was pulling way more power than expected,” he explains. After adjusting his usage patterns and upgrading to a newer model, Mike saves roughly $25 monthly, which adds up to $300 yearly.\n\nJennifer in Texas took a different approach with her converted home office shed. Her monitoring system revealed that her window AC unit was cycling inefficiently. “Adding better insulation and adjusting the thermostat based on actual usage data made a huge difference,” she notes. Her energy costs dropped by nearly half, and the shed stays more comfortable year-round. These real stories show that understanding your power usage is the first step toward meaningful savings.\n\n\nInstalling a power monitoring system in your shed isn’t just about tracking numbers on a screen—it’s about taking real control of your energy costs and creating a truly efficient workspace. Whether you’re running power tools for weekend projects, keeping a workshop heated, or simply charging equipment, understanding where your electricity goes gives you the power to make smarter decisions. The beauty of these systems is that they often pay for themselves within the first year through the savings they help you identify.\n\nNow’s the perfect time to take a closer look at your current shed setup. Walk out there with fresh eyes and ask yourself: Do I really know what’s using power? Are there devices running when they shouldn’t be? Could I be saving money without sacrificing functionality? Even small changes, like adjusting when you run certain equipment or identifying phantom loads, can add up to meaningful savings over time.\n\nThe good news is that getting started doesn’t require an electrical engineering degree or a massive budget. With today’s user-friendly monitoring systems and straightforward installation processes, you can begin optimizing your shed’s energy efficiency this weekend and start seeing results immediately.