Keep Your Shed Bone-Dry: Smart Tips for Basement Waterproofing Sheeting

Transform your basement from a damp liability into a dry, protected space with professional-grade waterproofing plastic sheeting. This critical moisture barrier, when properly installed, creates an impenetrable defense against groundwater intrusion, preventing mold growth, structural damage, and musty odors. Modern plastic sheeting solutions offer superior protection compared to traditional methods, combining high-density polyethylene with advanced vapor barrier technology to ensure lasting basement protection. Whether you’re tackling a DIY waterproofing project or preparing for professional installation, understanding the right type of plastic sheeting, proper installation techniques, and essential maintenance requirements will determine your project’s success. This guide explores everything you need to know about basement waterproofing plastic sheeting, from material selection to long-term performance, helping you make informed decisions to protect your home’s foundation and living space.

Why Your Shed Base Needs Waterproof Sheeting

Common Moisture Problems in Shed Bases

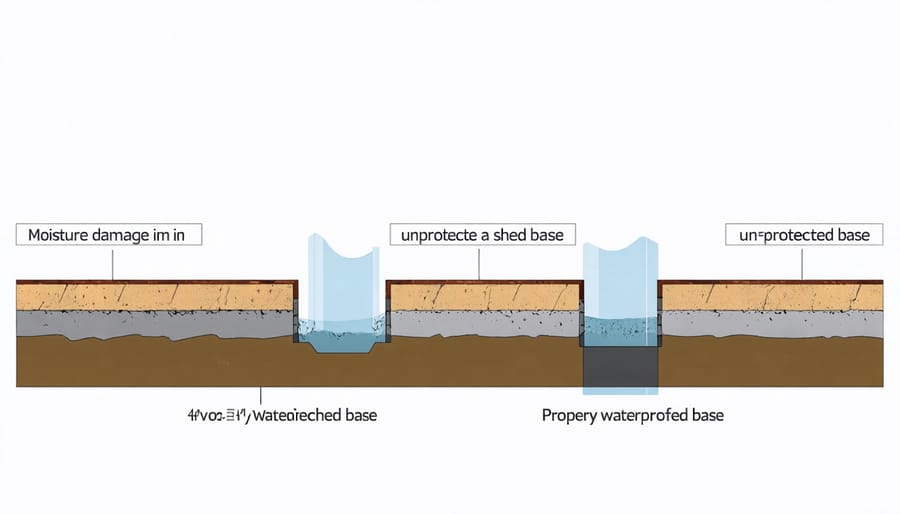

Ground moisture can wreak havoc on your shed if not properly addressed during installation. Without a proper shed foundation and waterproofing, you might encounter several frustrating issues. Common problems include wood rot at the base of your shed, warped flooring that creates uneven surfaces, and mold growth that can compromise both structural integrity and stored items.

Many homeowners notice these issues first through musty odors or dampness in their storage items. The foundation may also begin to sink unevenly into softened ground, causing doors to stick or gaps to form in the structure. Rust can develop on metal components, while wooden elements may show signs of swelling or deterioration.

These moisture-related problems often start subtly but can escalate quickly, especially during rainy seasons or in areas with high water tables. Left unchecked, they can significantly reduce your shed’s lifespan and potentially damage valuable stored items.

Benefits of Plastic Sheeting Protection

Installing proper waterproof plastic sheeting in your basement offers multiple layers of protection for your home. The primary advantage is its effectiveness in preventing moisture infiltration, keeping your basement dry and comfortable year-round. This barrier system not only blocks water from seeping through walls and floors but also helps control humidity levels, reducing the risk of mold and mildew growth.

The durability of quality plastic sheeting means long-lasting protection, often lasting 20 years or more with proper installation. It’s particularly effective at preventing minor cracks from becoming major issues and protecting your belongings from water damage. The smooth surface of plastic sheeting also makes it easier to clean and maintain your basement walls.

Beyond water protection, plastic sheeting can improve your basement’s energy efficiency by providing an additional insulating layer. This can lead to lower heating and cooling costs while creating a more comfortable living space. Many homeowners also appreciate how plastic sheeting can brighten their basement by reflecting light, making the space more inviting and functional.

Choosing the Right Waterproof Sheeting

Types of Waterproof Sheeting

When it comes to protecting your basement, choosing the right waterproof sheeting material is crucial. The most common types include polyethylene (PE), polypropylene (PP), and polyvinyl chloride (PVC) sheets, each offering unique benefits for different applications. The same principles apply when you need to waterproof your shed floor effectively.

Polyethylene sheeting, available in various thicknesses from 6 mil to 20 mil, is the most popular choice for basement waterproofing. The 6-mil thickness works well for basic moisture barriers, while 10-mil and above provide superior protection against water intrusion and are more puncture-resistant.

Cross-laminated polyethylene offers enhanced durability and tear resistance compared to standard PE sheets. This premium option is ideal for areas with high water pressure or challenging soil conditions.

PVC sheets, though more expensive, provide excellent chemical resistance and flexibility. They’re particularly effective in areas with aggressive soil conditions or where chemical contamination might be a concern.

For enhanced protection, some manufacturers offer sheets with textured surfaces or specialized coatings. These features improve grip during installation and provide better adhesion to concrete surfaces, creating a more reliable waterproof barrier.

Remember to consider your specific needs, soil conditions, and local climate when selecting waterproof sheeting. The right choice will depend on factors like water table levels, soil composition, and expected moisture exposure.

Quality Indicators to Look For

When selecting basement waterproofing plastic sheeting, several key indicators can help ensure you’re getting a quality product that will effectively protect your space. First, look for thickness measurements of at least 6 mils, though 10-20 mils is ideal for long-term durability. The material should feel sturdy and resistant to tearing when handled.

Color consistency is another important factor – high-quality sheets will have uniform coloring without thin spots or inconsistencies. Check that the material has UV protection if it will be exposed to sunlight during installation or at edges. The sheeting should also be clearly labeled as virgin polyethylene, rather than recycled material, for optimal performance.

Pay attention to the manufacturer’s warranty period – quality products typically offer 10-25 year guarantees. The sheeting should have clear installation instructions and be properly rated for below-grade use. Look for products that meet ASTM standards for vapor barriers and waterproofing membranes.

Examine the surface texture – quality sheeting should have a slightly textured finish that helps it grip concrete and prevent slipping. The material should also be flexible enough to conform to corners and irregular surfaces without cracking or losing its protective properties. Finally, check that seaming tape or adhesive options are available from the same manufacturer to ensure compatibility.

Installation Best Practices

Preparation Steps

Before installing waterproofing plastic sheeting, proper ground preparation is essential for effective moisture protection. Start by following our comprehensive site preparation guidelines to ensure a solid foundation. Clear the area of any vegetation, rocks, or debris that could puncture the sheeting. Level the ground using a rake and tamper, ensuring a slight grade away from your structure for proper drainage.

Measure the basement area carefully, adding an extra 2-3 feet on all sides to allow for adequate overlap and proper wall coverage. For accurate measurements, divide the space into rectangular sections and add them together. Remember to account for any corners, pipes, or other obstacles that might require additional material or special cutting.

Use a chalk line to mark your installation boundaries and create reference points for straight alignment. This preparation step is crucial for achieving a professional-looking installation that effectively protects your basement from moisture intrusion.

Laying the Sheeting

Start by clearing the installation area of any debris, rocks, or sharp objects that could puncture the sheeting. Roll out the waterproof barrier, ensuring it extends at least 6 inches up the basement walls. When working with multiple sheets, overlap the edges by 12 inches and seal them with waterproof tape specifically designed for this purpose.

Secure the sheeting to the walls using termination bars or masonry nails with washers, placing them every 12 inches along the top edge. Be careful not to create holes below the expected water line. For corners, create neat folds rather than cutting the material, as this maintains the waterproof integrity of the barrier.

Work systematically across the floor, smoothing out any wrinkles or air pockets as you go. Use waterproof adhesive in areas where the sheeting meets pipes or other penetrations, creating a tight seal around these potential weak points. For added protection, consider adding a second layer in high-risk areas or where water pressure is expected to be significant.

Once the main sheeting is in place, inspect all seams and transitions carefully. Pay special attention to corners and joints, as these are common areas for water infiltration. Finally, protect the installed barrier with a layer of drainage board or gravel before completing your basement floor installation.

Sealing and Finishing

The final step in basement waterproofing is ensuring all seams and edges are properly sealed for complete protection. Start by overlapping adjacent sheets by at least 6 inches and securing them with waterproof tape designed specifically for vapor barriers. Pay special attention to corners and joints where walls meet the floor, as these areas are particularly vulnerable to moisture penetration.

Apply a continuous bead of waterproof sealant along the top edges where the plastic sheeting meets foundation walls. For added protection, consider installing a termination bar – a sturdy strip that mechanically fastens the sheeting to the wall while compressing it against the sealant.

Any penetrations through the barrier, such as pipes or utility lines, require special attention. Cut the sheeting to fit snugly around these obstacles and use pipe boots or collars specifically designed for vapor barriers. Seal these fittings with appropriate tape or mastic sealant.

Once all seams and penetrations are properly sealed, inspect the entire installation carefully. Look for any tears, gaps, or loose areas that might compromise the waterproofing system. Small repairs can be made easily with specialized repair tape or patches designed for vapor barriers.

Maintenance and Long-term Care

Regular inspections of your basement waterproofing plastic sheeting are essential for long-term effectiveness. Check the material every six months for tears, holes, or separating seams. Clean the surface gently with a soft brush and mild soap solution to remove dirt and debris that could cause degradation. Keep the area around the sheeting free from sharp objects and stored items that might puncture the material.

If you notice any damage, patch small holes immediately using waterproof tape designed for plastic sheeting. For larger tears, consider replacing that section entirely. Maintain proper drainage around your foundation, as this reduces pressure on the waterproofing system. During seasonal changes, pay special attention to areas where the sheeting meets foundation walls or floor joints, as these are common points where problems can develop.

Remember to document any repairs or maintenance performed, which helps track the sheeting’s performance over time and plan for eventual replacement.

Proper basement waterproofing with plastic sheeting is a crucial investment in your home’s longevity and your family’s comfort. By selecting the right mil thickness, ensuring proper installation with careful overlap and secure fastening, and regularly inspecting for damage, you can create an effective moisture barrier that protects your basement for years to come. Remember that while plastic sheeting is an excellent waterproofing solution, it works best as part of a comprehensive waterproofing system that includes proper drainage and regular maintenance. Taking the time to waterproof correctly now can save you thousands in potential water damage repairs and provide peace of mind during heavy rains and spring thaws. Make sure to follow local building codes and consider professional installation for complex situations to ensure the best possible protection for your basement.