Make Your Shed a Year-Round Haven with Ceramic Thermal Barrier Coating

Transform your shed into a year-round comfortable space with ceramic thermal barrier coating, an advanced insulation technology that revolutionizes temperature control in outdoor structures. This innovative coating system creates a microscopic barrier that reflects heat in summer and retains warmth in winter, delivering up to 40% better temperature regulation than traditional insulation methods.

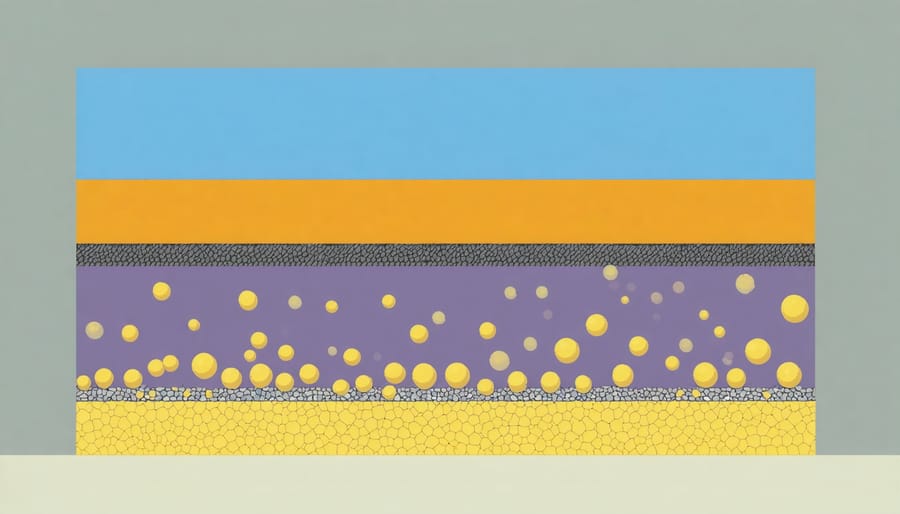

Applied as a specialized paint-like substance, ceramic thermal barrier coating works by embedding millions of hollow ceramic microspheres in a durable resin base. These tiny spheres create an effective thermal break, preventing heat transfer while remaining breathable and moisture-resistant. For shed owners battling extreme temperatures or seeking energy-efficient solutions, this coating offers a practical, long-lasting answer that can be applied in a single weekend.

Beyond temperature control, this modern coating technology provides additional benefits including sound dampening, condensation prevention, and enhanced structural protection – making it an ideal investment for any shed owner looking to maximize their storage space’s functionality and longevity.

How Ceramic Thermal Barrier Coating Works

The Magic of Microscopic Ceramic Spheres

At the heart of ceramic thermal barrier coatings are tiny ceramic spheres, each smaller than a grain of sand. These microscopic spheres work like countless tiny mirrors, bouncing heat away from your shed’s surface. When sunlight hits the coating, these ceramic particles create a remarkable barrier that reflects heat rather than absorbing it. Think of them as a protective shield made up of millions of miniature umbrellas, each one working to keep your shed cooler.

What makes these spheres truly special is their hollow nature. Like tiny vacuum-sealed bubbles, they create dead air spaces that naturally resist heat transfer. When applied to your shed’s surface, these ceramic spheres form multiple layers that work together, creating an effective thermal barrier that helps maintain a more comfortable temperature inside your storage space all year round. It’s like giving your shed its own climate-control system, powered by simple but clever science.

Why It’s Different from Traditional Insulation

Unlike traditional insulation methods that rely on thick layers of material like fiberglass or foam, ceramic thermal barrier coating works through advanced thermal reflection technology. This ultra-thin coating, often just millimeters thick, creates an effective barrier that both reflects heat and prevents thermal transfer. It’s particularly practical for shed owners because it doesn’t take up valuable storage space or require complex installation procedures.

The coating bonds directly to your shed’s surfaces, creating a seamless protective layer that won’t sag, settle, or deteriorate over time like conventional insulation materials. It’s also moisture-resistant, which means you won’t have to worry about mold or mildew growth that sometimes occurs with traditional batting or foam insulation. Plus, it can be applied to virtually any surface – walls, ceiling, or even doors – without changing your shed’s interior dimensions or requiring additional framing support.

Benefits for Your Storage Shed

Temperature Control Year-Round

Among the most effective temperature control solutions, ceramic thermal barrier coating works like a thermos for your shed, maintaining comfortable temperatures year-round. During hot summer months, this innovative coating reflects solar radiation away from your shed’s surfaces, significantly reducing heat absorption. The ceramic particles in the coating create a barrier that prevents excessive heat from penetrating the walls, keeping your stored items cool and protected.

In winter, the same coating works in reverse, helping to retain indoor warmth by minimizing heat loss through the walls. The microscopic ceramic spheres trap air pockets, creating an insulating layer that works much like a warm blanket around your shed. This dual-action protection means your shed stays up to 15-20 degrees cooler in summer and noticeably warmer in winter, without the need for additional heating or cooling systems.

For gardeners and DIY enthusiasts, this consistent temperature regulation helps protect sensitive tools, paint supplies, and seasonal equipment from extreme temperature fluctuations that could otherwise cause damage or deterioration.

Protection for Stored Items

Ceramic thermal barrier coating provides exceptional protection for your valuable belongings, helping to protect your stored items from temperature fluctuations and moisture damage. Tools and equipment stored in your shed, such as power tools, lawn mowers, and garden implements, stay safer when protected from extreme temperature swings that can lead to rust and deterioration.

The coating creates a stable environment that’s particularly beneficial for temperature-sensitive items like paints, adhesives, and electronics. By maintaining more consistent temperatures, you’ll reduce the risk of warping, cracking, or degradation of wooden furniture and delicate materials. Many homeowners have reported that their seasonal decorations and family keepsakes remain in better condition when stored in spaces treated with ceramic thermal barrier coating.

Additionally, the coating’s moisture-resistant properties help prevent the growth of mold and mildew, keeping stored fabrics, papers, and cardboard boxes dry and clean. This means your holiday decorations, camping gear, and cherished memories stay preserved just as you left them, ready for their next use.

Application Process Made Simple

Preparation Steps

Before applying ceramic thermal barrier coating to your shed, proper surface preparation is essential for optimal results. Start by thoroughly cleaning the surface using a pressure washer or a sturdy brush with warm, soapy water to remove dirt, debris, and loose paint. Allow the surface to dry completely.

Next, inspect the walls for any damage, cracks, or holes. Fill these imperfections with appropriate patching compound and sand smooth once dried. If there’s existing paint, check for peeling or flaking areas and sand them down to create a uniform surface.

For metal surfaces, remove any rust using a wire brush or sandpaper, then wipe with mineral spirits to ensure a clean surface. For wooden surfaces, sand lightly to create a slightly rough texture that helps the coating adhere better.

Apply a suitable primer recommended for your specific surface type and let it cure according to the manufacturer’s instructions. Once the primer is fully dry, wipe down the surface one final time with a tack cloth to remove any dust or debris before applying the ceramic thermal barrier coating.

Remember to wear protective gear like gloves, safety glasses, and a dust mask during the preparation process.

Application Tips

For the best results when applying ceramic thermal barrier coating, start with a thoroughly cleaned and dry surface. Remove any dirt, rust, or loose paint using a wire brush and sandpaper. If you’re working on metal surfaces, consider using a degreaser to ensure proper adhesion.

Apply the coating on a day when temperatures are between 50-85°F, with moderate humidity. Use a high-quality paint sprayer for even coverage, though roller application can work for smaller areas. Work in thin, even layers rather than one thick coat – typically, 2-3 layers provide optimal protection.

Allow each layer to dry completely before applying the next coat, usually 2-4 hours depending on weather conditions. For best results, apply subsequent coats at right angles to the previous layer. After the final coat, let the surface cure for at least 24 hours before exposure to heat or moisture.

Remember to wear appropriate safety gear, including a respirator mask, safety glasses, and gloves. Work in a well-ventilated area and cover nearby surfaces to protect them from overspray.

Common Mistakes to Avoid

When applying ceramic thermal barrier coating, avoid rushing through surface preparation, as this can lead to poor adhesion and premature peeling. Don’t skip the cleaning process or apply the coating on damp surfaces, as moisture can compromise its effectiveness. Another common mistake is applying too thick a layer in one go – multiple thin coats work better than one heavy application. Keep an eye on temperature and humidity levels during application, as extreme conditions can affect the coating’s performance. Ensure proper ventilation during application, but avoid excessive airflow that could cause uneven drying. Finally, don’t forget to protect surrounding areas from overspray, and always allow adequate curing time between coats for optimal results.

Maintenance and Longevity

To ensure your ceramic thermal barrier coating performs optimally and lasts for years, proper maintenance is essential. Regular inspections every six months can help identify any potential issues early on. Check for signs of wear, peeling, or damage, particularly around areas exposed to frequent temperature changes or mechanical stress.

Clean the coated surfaces gently using a soft brush or cloth with mild soap and water. Avoid harsh chemical cleaners or abrasive materials that could damage the coating. If you notice any dirt or debris accumulation, remove it promptly to maintain the coating’s effectiveness.

When properly maintained, ceramic thermal barrier coatings typically last between 5 to 10 years in residential applications. However, this lifespan can vary depending on several factors, including:

– Environmental conditions

– Quality of initial application

– Frequency of temperature fluctuations

– Physical wear and tear

– Exposure to UV rays

To extend the coating’s life, consider applying a protective top coat every 2-3 years. This additional layer helps shield the primary coating from environmental factors and physical damage. If you notice any damaged areas, address them quickly with touch-up applications to prevent further deterioration.

Keep detailed records of maintenance activities and inspections. This documentation helps track the coating’s performance and anticipate when replacement might be necessary. For best results, schedule professional inspections annually, especially if you notice any significant changes in the coating’s appearance or performance.

Remember that proper maintenance not only extends the coating’s lifespan but also ensures it continues to provide optimal thermal protection for your shed throughout its service life.

Ceramic thermal barrier coating represents a game-changing solution for homeowners looking to enhance their shed’s comfort and energy efficiency. This innovative technology not only provides superior temperature regulation but also offers long-lasting protection for your outdoor structure. By investing in ceramic thermal barrier coating, you’re choosing a cost-effective way to maintain comfortable temperatures year-round while potentially reducing your energy costs.

The benefits are clear: exceptional heat reflection, moisture resistance, and durability that can last for years with proper maintenance. Whether you’re storing temperature-sensitive items or using your shed as a workspace, this coating can transform your space into a more functional and comfortable environment.

Don’t let extreme temperatures limit how you use your shed. Take action today by exploring ceramic thermal barrier coating options for your structure. With easy application methods and minimal maintenance requirements, it’s a practical solution that delivers impressive results. Make the smart choice for your shed’s future and enjoy the peace of mind that comes with superior thermal protection.