Metal Shed Ramps That Make Storage Access a Breeze

Transform your metal storage sheds into accessible workspaces with a properly installed metal ramp. Select aluminum ramps rated for at least 1,500 pounds to safely accommodate heavy equipment and lawn machinery. Install adjustable ramps with anti-slip surfaces to maintain stability during wet conditions and ensure year-round functionality. Position your ramp at a maximum 20-degree angle, allowing one foot of length for every inch of height, to create a safe incline for both powered and manual equipment. Consider wider ramps (36 inches minimum) with raised edges to prevent accidental roll-offs and provide confident navigation during loading and unloading. These durable additions not only enhance storage accessibility but also increase property value through improved functionality and safety features.

Why Your Metal Storage Shed Needs a Proper Ramp

Safety First: Preventing Accidents and Injuries

Using a metal ramp for your storage shed isn’t just about convenience – it’s a crucial safety measure that prevents common accidents and injuries. When moving heavy equipment or bulky items, a properly installed ramp eliminates the risk of lifting injuries and reduces the chance of trips and falls that often occur when using makeshift solutions like wooden planks or blocks.

The textured, non-slip surface of quality metal ramps provides secure footing even in wet conditions, while side rails offer additional protection against accidental falls. The ramp’s gradual incline ensures safer movement of wheeled equipment like lawn mowers and wheelbarrows, preventing dangerous tilting or rolling.

Remember to always check your ramp’s weight capacity before use, keep the surface clean and debris-free, and ensure proper anchoring to both the ground and shed threshold. Following these safety guidelines not only protects you and your family but also preserves your valuable equipment and storage items.

Protecting Your Equipment and Stored Items

A quality metal ramp does more than just provide access – it actively protects your valuable equipment and stored items during transport. The smooth, continuous surface eliminates the bumps and jolts that can damage lawn mowers, ATVs, or delicate furniture when moving them in and out of your shed. The gentle incline prevents items from tipping or sliding, while the raised edges help keep wheels aligned and prevent accidents.

When using a proper ramp, you’ll avoid the strain and potential damage that comes from lifting heavy items over a threshold or navigating makeshift solutions. The non-slip surface provides reliable traction in all weather conditions, protecting both your items and yourself from slips and falls. Additionally, a well-installed metal ramp helps prevent wear and tear on your shed’s entrance, maintaining the structural integrity of your storage space while keeping your belongings safe and secure during every use.

Choosing the Right Metal Ramp for Your Shed

Weight Capacity Requirements

Determining the right weight capacity for your metal ramp is crucial for safe and effective use of your storage shed. Start by considering the heaviest items you’ll need to move up and down the ramp. Common items like riding lawn mowers typically weigh between 400-600 pounds, while ATVs can weigh up to 800 pounds or more.

A good rule of thumb is to choose a ramp with a weight capacity that’s at least 1.5 times the weight of your heaviest item. This provides a safety buffer and accounts for the combined weight of the item and the person moving it. For residential use, most homeowners find that ramps rated for 1,000 to 1,500 pounds are sufficient.

Don’t forget to factor in dynamic weight – the force created when rolling items up and down the ramp. This can temporarily increase the effective weight on your ramp. If you’re regularly moving heavy equipment or multiple items, consider opting for a higher capacity rating.

For peace of mind, always check the manufacturer’s specifications and weight ratings before making your final choice. Remember, it’s better to have more capacity than you need than to risk damage or injury with an underrated ramp.

Size and Slope Considerations

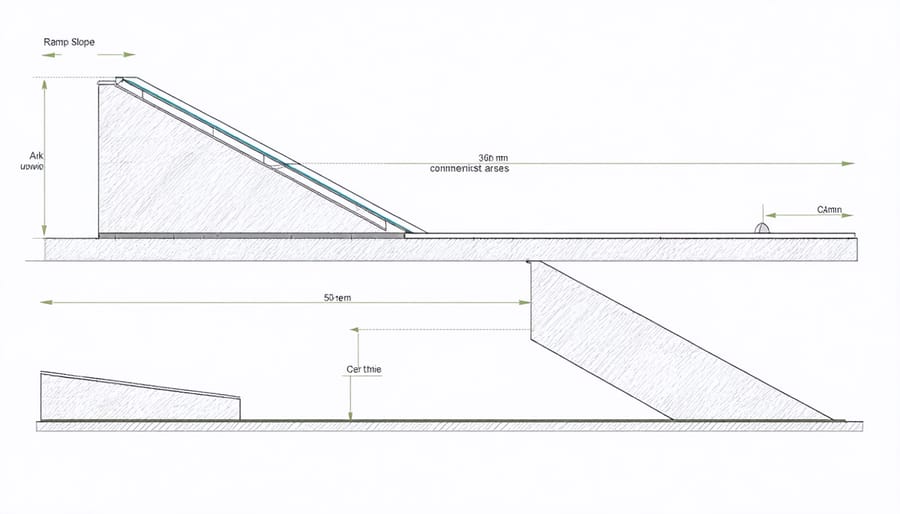

When planning your storage shed ramp, getting the dimensions and slope right is crucial for safe and easy access. For most residential storage sheds, a ramp width of 36 to 48 inches provides comfortable clearance for wheelbarrows and lawn equipment. The length of your ramp will depend on your desired slope angle.

The ideal slope for a shed ramp is between 1:12 and 1:8 (rise:run ratio). This means for every inch of height, you’ll need 8-12 inches of ramp length. For example, if your shed threshold is 8 inches high, your ramp should be 64-96 inches long for optimal safety and usability.

Remember to account for your specific needs. If you’ll be moving heavy equipment or using a riding mower, opt for a gentler slope (1:12) and wider width. For lighter use with hand tools and push mowers, a steeper slope (1:8) may suffice.

Pro tip: Add an extra 6 inches to your planned width if you’re installing handrails, which we strongly recommend for safety. Also, ensure your ramp extends at least 6 inches beyond your shed’s doorway for smooth transitions.

Surface Texture and Weather Resistance

Metal ramps for storage sheds feature specialized surface textures designed to prevent slips and falls in all weather conditions. Most quality ramps include raised diamond or serrated patterns that provide excellent traction, even when wet. These textured surfaces are particularly important during rainy seasons or in areas with frequent precipitation. The ramps are typically constructed using weather-resistant materials that won’t corrode or deteriorate when exposed to the elements. Many manufacturers apply anti-rust coatings and treatments to enhance durability, ensuring your ramp maintains its grip and structural integrity for years to come. For added safety, some models include side rails or raised edges that help prevent wheels from slipping off the sides while providing additional stability during use.

Installation Tips for Metal Shed Ramps

Ground Preparation

Before installing your metal ramp, proper foundation preparation is essential for safety and longevity. Start by clearing the installation area of any vegetation, rocks, or debris. Using a level, check that the ground slopes away from your shed by approximately 1 inch for every 8 feet to ensure proper drainage.

For the ramp’s base, create a firm foundation using crushed gravel or concrete blocks. Compact the soil thoroughly and add a 2-3 inch layer of gravel, tamping it down to create a stable surface. This prevents settling and shifting that could make your ramp unstable over time.

Mark the exact placement of your ramp using stakes and string to ensure proper alignment with your shed’s doorway. The ground should be level from side to side but maintain a slight slope away from the shed for drainage. Consider installing landscape fabric underneath the gravel to prevent weed growth and maintain the foundation’s integrity.

For areas with poor soil conditions or frequent rain, you might want to add additional drainage solutions like a French drain system along the sides of your planned ramp location.

Secure Mounting Methods

Properly securing your metal ramp to your storage shed is crucial for safety and functionality. The most common and reliable method is using heavy-duty bolts and brackets at both the shed threshold and ground contact points. Start by installing L-brackets at the top of the ramp where it meets the shed door, using rust-resistant bolts and washers to prevent corrosion.

For ground anchoring, concrete anchors provide excellent stability. Drill holes into your concrete pad or foundation, then secure the ramp’s base using expansion bolts. If you’re installing on soil, consider using ground stakes or auger-style anchors driven at least 18 inches deep for maximum stability.

Some ramps come with pre-drilled mounting holes, making installation straightforward. If not, carefully mark and drill your mounting points, ensuring they align perfectly with your shed’s entrance. Always use stainless steel or galvanized hardware to prevent rust and maintain the ramp’s integrity over time.

Remember to check and tighten all mounting hardware regularly, especially after heavy use or severe weather conditions. This simple maintenance step will ensure your ramp remains secure and safe for years to come.

Maintenance and Care

Regular maintenance of your metal ramp ensures its longevity and safe operation. Start by implementing a monthly cleaning routine using a stiff brush to remove dirt, leaves, and debris that can accumulate on the surface. For stubborn grime, use mild soap and water, avoiding harsh chemicals that might damage the metal’s protective coating.

After cleaning, inspect your ramp thoroughly for any signs of rust, particularly in areas where water tends to collect. If you spot rust formation, address it immediately by gently sanding the affected area and applying a rust-inhibiting primer followed by matching paint designed for outdoor metal surfaces.

Check all mounting points and hardware quarterly, tightening any loose bolts or screws. Pay special attention to the connection points between the ramp and your shed, as these areas experience the most stress during use. Apply a small amount of marine-grade grease to hinges if your ramp has a folding mechanism.

During winter months, avoid using salt or harsh de-icing chemicals on your metal ramp. Instead, use sand or cat litter for traction when needed. Keep snow and ice cleared promptly to prevent moisture damage and maintain safe access to your shed.

For added protection, consider applying a clear protective coating annually. This extra layer helps guard against weather damage and extends the life of your ramp. Store portable ramps in a covered area when not in use for extended periods, and always ensure proper drainage around your permanent ramp installation to prevent water pooling.

Remember to address any damage promptly – small issues can quickly become bigger problems if left unattended. With proper care, your metal ramp can provide reliable service for many years.

Choosing the right metal ramp for your storage shed is an investment in safety, convenience, and accessibility. Throughout this guide, we’ve explored the essential factors to consider, from weight capacity and dimensions to materials and installation requirements. Remember that the perfect ramp depends on your specific needs, including the items you’ll be moving, frequency of use, and local weather conditions.

For optimal results, always prioritize quality materials and proper installation. A well-installed metal ramp not only enhances your shed’s functionality but also increases its overall value. Don’t forget to perform regular maintenance checks, keeping the ramp clean and free from debris, and addressing any signs of wear promptly.

Whether you’re storing lawn equipment, motorcycles, or seasonal items, investing in a sturdy metal ramp will make your storage shed more accessible and safer to use. By following the guidelines we’ve discussed and considering your unique requirements, you’ll be well-equipped to select and maintain the perfect ramp for your storage shed.

Remember to consult local building codes and consider professional installation if you’re unsure about handling the project yourself. With proper planning and care, your metal ramp will serve you reliably for years to come.