Smart Barn Ventilation That Keeps Your Storage Shed Fresh Year-Round

Proper barn ventilation stands as the cornerstone of agricultural building design, protecting both valuable equipment and stored materials from moisture damage, mold growth, and premature deterioration. Modern ventilation systems combine natural airflow principles with cutting-edge mechanical solutions to maintain optimal temperature and humidity levels year-round. From ridge vents that harness thermal dynamics to automated fan systems that respond to environmental changes, today’s barn ventilation options offer farmers and property owners unprecedented control over their storage conditions. Whether protecting hay from spoilage, preserving machinery from rust, or maintaining ideal conditions for livestock feed, an effective ventilation strategy transforms a basic storage structure into a controlled environment that actively preserves its contents. Understanding these systems isn’t just about installation – it’s about creating a sustainable, efficient space that protects investments and enhances agricultural operations for years to come.

Why Your Storage Shed Needs Proper Ventilation

Moisture Control and Mold Prevention

Proper ventilation plays a crucial role in helping prevent moisture damage and mold growth in your barn. When warm, humid air becomes trapped inside, it creates the perfect environment for mold to thrive and can lead to rotting wood, rusted metal, and damaged belongings. A well-designed ventilation system creates continuous airflow that removes excess moisture from the air before it can cause problems.

During warmer months, ventilation helps expel hot, humid air that rises to the ceiling, while drawing in fresher, drier air through lower vents. In winter, this same airflow helps prevent condensation from forming on cold surfaces, which is especially important when temperature differences between inside and outside are significant.

To maximize moisture control, ensure your ventilation system includes both intake and exhaust vents positioned strategically throughout your barn. This creates a natural flow that keeps air moving and humidity levels in check year-round.

Temperature Regulation

Proper ventilation plays a crucial role in temperature control in storage sheds, helping maintain an optimal environment for your stored items. During warmer months, effective ventilation systems prevent heat buildup that could damage sensitive equipment or create uncomfortable working conditions. The natural airflow helps reduce moisture accumulation, which is especially important for protecting tools, machinery, and seasonal decorations from rust and mold.

In winter, proper ventilation continues to work alongside your heating system, preventing cold spots and reducing condensation that typically forms when warm air meets cold surfaces. This balance is particularly important for storing temperature-sensitive items like paints, electronics, or garden chemicals. By maintaining consistent airflow throughout the year, your barn ventilation system creates a stable environment that protects your investments and extends the life of stored materials.

Remember that different storage items may require varying temperature ranges, so consider adjusting your ventilation settings seasonally to accommodate these needs.

Essential Components of an Effective Ventilation System

Natural Ventilation Options

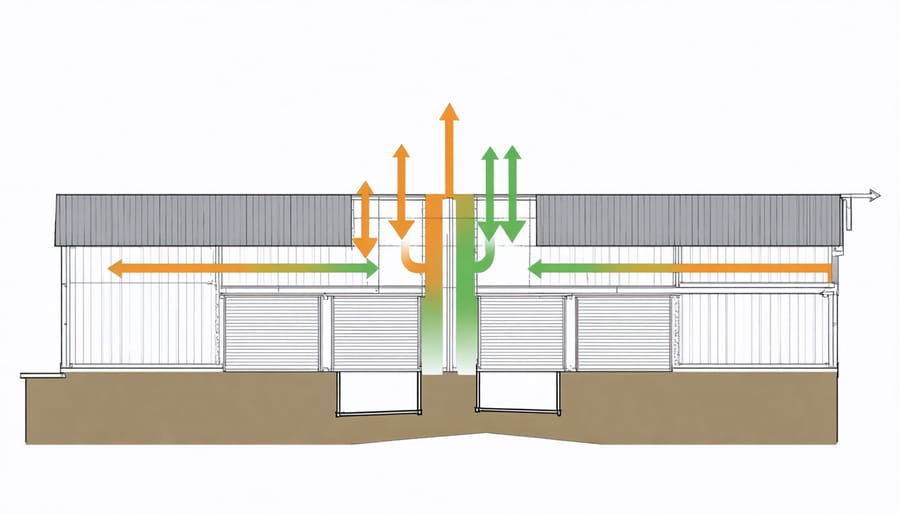

Natural ventilation offers a cost-effective and energy-efficient way to maintain proper airflow in your storage barn. The key components of a proper roof ventilation design include ridge vents, soffit vents, and gable vents, working together to create a continuous flow of fresh air.

Ridge vents run along the peak of your barn’s roof, allowing warm, moist air to escape naturally. These low-profile vents blend seamlessly with your roofline while providing excellent air circulation. When paired with soffit vents, they create an efficient system that takes advantage of the natural stack effect, where warm air rises and exits through the ridge while drawing in fresh air through the soffits.

Soffit vents, installed under the roof’s overhang, serve as intake points for fresh air. They’re particularly effective because they’re protected from rain and snow, allowing for continuous ventilation even during adverse weather conditions. For optimal performance, ensure your soffit vents remain clear of debris and insulation.

Gable vents, positioned at the ends of your barn near the roof peak, provide additional cross-ventilation. These vents work especially well in combination with ridge and soffit vents, creating multiple air paths that help maintain consistent temperatures and reduce moisture buildup. When designing your ventilation system, consider installing gable vents on opposite ends to maximize airflow through your storage space.

Mechanical Ventilation Solutions

Mechanical ventilation offers powerful and reliable solutions for maintaining optimal airflow in your barn or storage shed. At the heart of these systems are strategically placed electric fans, which come in various sizes to suit different space requirements. Wall-mounted exhaust fans are particularly effective, pulling stale air out while fresh air enters through intake vents.

Power ventilators installed on the roof provide another excellent option, creating upward air movement that helps regulate temperature and humidity levels. These units are especially useful during hot summer months when natural airflow might not be sufficient.

For maximum convenience and efficiency, automated ventilation systems take the guesswork out of maintaining proper air circulation. These smart systems use thermostats and humidity sensors to activate fans automatically when conditions require it. Some advanced setups even include programmable controls that adjust ventilation based on time of day or seasonal changes.

Multi-speed fans offer flexibility in airflow control, allowing you to increase ventilation during peak humidity periods and reduce it during cooler weather. For larger barns, a combination of gable fans and wall-mounted units creates a comprehensive cross-ventilation system that ensures no corner goes unventilated.

While mechanical ventilation systems require an initial investment and ongoing electricity costs, they provide reliable, year-round performance that protects your stored items and maintains a comfortable environment for any barn activities.

DIY Installation Tips

Tools and Materials Needed

To properly install and maintain your barn ventilation system, you’ll need several essential tools and materials. Start with basic measuring tools including a tape measure, level, and pencil for marking installation points. You’ll also need a power drill with various drill bits, a screwdriver set, and a utility knife for cutting materials to size.

For the ventilation components, gather ridge vents, soffit vents, and any necessary vent covers or screens to keep out unwanted wildlife. Weather stripping and caulk are crucial for ensuring proper sealing around vents. If you’re installing powered ventilation, you’ll need an electric fan, wiring materials, and potentially a thermostat controller.

Safety equipment is essential – grab a sturdy ladder, safety glasses, work gloves, and a dust mask. For installation, you’ll want self-tapping screws, mounting brackets, and appropriate fasteners for your barn’s construction material. Don’t forget some basic cleaning supplies like a wire brush and rags to prepare surfaces for installation.

A helper is highly recommended for safety and efficiency, especially when working on ladders or handling larger components.

Installation Process

Installing a barn ventilation system is a straightforward process when you follow proper safety guidelines and planning. Start by conducting a thorough assessment of your barn’s layout and identifying the optimal locations for vents and fans. This typically includes spots near the roof peak and along the sidewalls for maximum air circulation.

Before beginning installation, gather all necessary tools and materials, including safety equipment like gloves, goggles, and a sturdy ladder. If you’re installing electrical components, consider hiring a licensed electrician to ensure proper wiring and compliance with local codes.

For ridge vent installation, begin by marking the cutting lines along your roof ridge. Remove any existing ridge caps and cut through the roof deck following manufacturer specifications. Install the ridge vent material and secure it with appropriate fasteners, ensuring proper overlap at joints.

When installing wall vents, carefully cut openings according to the manufacturer’s template. Install weather stripping around the openings and secure the vent housing with rust-resistant screws. For powered ventilation systems, mount exhaust fans at recommended heights, typically 8-10 feet above the floor.

Remember these important safety considerations:

– Always work with a partner when using ladders

– Verify weight ratings for roof access

– Turn off power when working with electrical components

– Use appropriate fall protection equipment

– Follow manufacturer guidelines for spacing and sizing

After installation, test the system thoroughly to ensure proper airflow and operation. Make any necessary adjustments to fan speeds or vent positions to achieve optimal ventilation. Consider installing a simple thermometer and humidity gauge to monitor the system’s effectiveness.

Maintenance and Troubleshooting

Regular maintenance of your barn ventilation system is essential for optimal performance and longevity. Start by conducting monthly visual inspections of all components, including fans, vents, and ductwork. Clean fan blades and guards every three months to prevent dust buildup, which can reduce efficiency and increase energy costs.

Check weather stripping and seals around vents seasonally, replacing any damaged materials to prevent air leaks. Lubricate moving parts according to manufacturer specifications, typically every six months, to ensure smooth operation and prevent wear.

Common issues you might encounter include unusual noises, reduced airflow, or inconsistent temperatures. If you hear rattling or squealing, check for loose components or worn bearings. Decreased airflow often results from clogged filters or dirty fan blades – a thorough cleaning usually resolves this. For temperature control problems, verify that thermostats are working correctly and properly positioned away from direct sunlight or heat sources.

If your system isn’t performing well despite basic maintenance, look for blocked air inlets or exhaust fans. Sometimes, birds nest in vents or debris accumulates in ductwork. Consider installing protective screens if this is a recurring issue.

When troubleshooting doesn’t solve the problem, don’t hesitate to contact a professional, especially for electrical issues or major mechanical failures. Keep a maintenance log to track service dates and recurring problems, making it easier to spot patterns and prevent future issues.

Proper barn ventilation is more than just a comfort feature – it’s essential for protecting your stored items and maintaining a healthy storage environment. Throughout this guide, we’ve explored how effective ventilation systems prevent moisture buildup, regulate temperature, and extend the life of your barn structure. Remember that the best ventilation solution combines both passive and active elements, working together to create consistent airflow year-round. By implementing the right combination of vents, fans, and monitoring systems, you’ll create an optimal environment for whatever you’re storing. Regular maintenance and seasonal adjustments will ensure your ventilation system continues performing effectively for years to come. Don’t underestimate the impact of proper airflow – it’s one of the most important investments you can make in protecting your barn and its contents.