Heat-Treated Skids: The Secret to a Long-Lasting Shed Foundation

Heat-treated skids form the backbone of a proper shed foundation, protecting your investment from moisture damage and extending its lifespan by decades. These pressure-treated wooden beams, typically crafted from Southern Yellow Pine, undergo an intensive heating process that removes moisture and creates a barrier against rot, insects, and ground contact deterioration. Unlike untreated lumber that can fail within years, heat-treated skids maintain their structural integrity for 20+ years when properly installed and maintained. For DIY enthusiasts and homeowners seeking a reliable storage solution, these engineered foundation components eliminate the common headaches of shifting, sinking, and premature wood decay that plague many backyard sheds. By elevating your structure and providing crucial ground clearance, heat-treated skids deliver professional-grade durability while remaining cost-effective and straightforward to install.\n\n\n

Why Heat-Treated Wood Matters for Your Shed

\n\n

Protection Against Moisture and Decay

\n\nHeat treatment provides exceptional protection against moisture and decay, making these skids a smart choice for long-term shed foundations. During the heat-treating process, wood is exposed to high temperatures that eliminate moisture and modify its cellular structure, creating a naturally resistant barrier against rot, mold, and fungal growth.\n\nUnlike untreated wood that can quickly deteriorate when exposed to ground moisture, heat-treated skids maintain their structural integrity for years. The treatment process reduces the wood’s ability to absorb water, which means less swelling, warping, and cracking over time. This enhanced moisture resistance is particularly valuable in areas with high rainfall or humid climates.\n\nMany homeowners appreciate that this protection is achieved without the use of chemical preservatives, making heat-treated skids an environmentally friendly choice. The natural preservation process creates a stable foundation that won’t leach harmful substances into your soil or surrounding environment. With proper installation and minimal maintenance, heat-treated skids can easily last 15-20 years, providing reliable support for your shed while protecting your investment from ground-level moisture damage.\n\n

\n

\n\n\n

Pest Resistance Benefits

\n\nOne of the most significant advantages of heat-treated skids is their remarkable ability to prevent pest infestations. During the heat treatment process, these wooden supports are subjected to temperatures reaching 140°F (60°C) for at least 30 minutes, effectively eliminating any existing insects, larvae, or eggs that might be present in the wood.\n\nThis treatment creates an inhospitable environment for common wood-destroying pests like termites, carpenter ants, and wood-boring beetles. Unlike chemical treatments that can wear off over time, heat treatment permanently alters the wood’s cellular structure, making it naturally resistant to future insect invasions. This means you won’t have to worry about unwanted visitors compromising your shed’s foundation or spreading to nearby structures.\n\nFor homeowners, this translates to peace of mind and reduced maintenance costs over time. You won’t need to schedule regular pest control treatments or inspect for signs of infestation as frequently. This natural pest resistance is particularly valuable for storage spaces containing valuable items or equipment that you want to protect from pest-related damage.\n\n\n

\n

\n\n\n

Heat-Treated vs. Regular Pressure-Treated Skids

\n\nWhen choosing skids for your shed foundation, you’ll likely encounter two main options: heat-treated and regular pressure-treated wood. Both treatments aim to protect the wood, but they work in different ways and offer distinct advantages.\n\nHeat-treated skids undergo a carefully controlled heating process that reaches temperatures between 180-220 degrees Fahrenheit. This process essentially “bakes” the wood, removing moisture and naturally occurring compounds that attract insects and promote decay. The result is a chemical-free product that’s particularly well-suited for environmentally conscious homeowners.\n\nRegular pressure-treated skids, on the other hand, are infused with chemical preservatives under high pressure. These chemicals help protect the wood against insects, rot, and moisture damage. While highly effective, some homeowners prefer to avoid these chemical treatments, especially if the shed will be used to store garden tools or house sensitive items.\n\nHere’s what makes heat-treated skids stand out:\n- They’re completely chemical-free\n- Safe for organic gardens and food storage\n- Naturally resistant to pests and decay\n- More dimensionally stable with less warping\n- Environmentally friendly\n- Ideal for international shipping (meets ISPM 15 standards)\n\nRegular pressure-treated skids offer these benefits:\n- Generally more affordable\n- Widely available at most lumber yards\n- Proven track record of durability\n- Effective against ground contact decay\n- Often comes with lengthy warranties\n\nFor most residential shed applications, heat-treated skids are an excellent choice, especially if you’re concerned about chemical exposure or environmental impact. However, in areas with extreme moisture or severe pest problems, pressure-treated skids might be more suitable. Consider your specific needs, local climate, and intended use when making your selection.\n\nRemember that proper installation and maintenance are just as important as the treatment method you choose. Either option will serve you well when correctly installed and protected from excessive moisture.\n\n\n

Installation Best Practices

\n\n

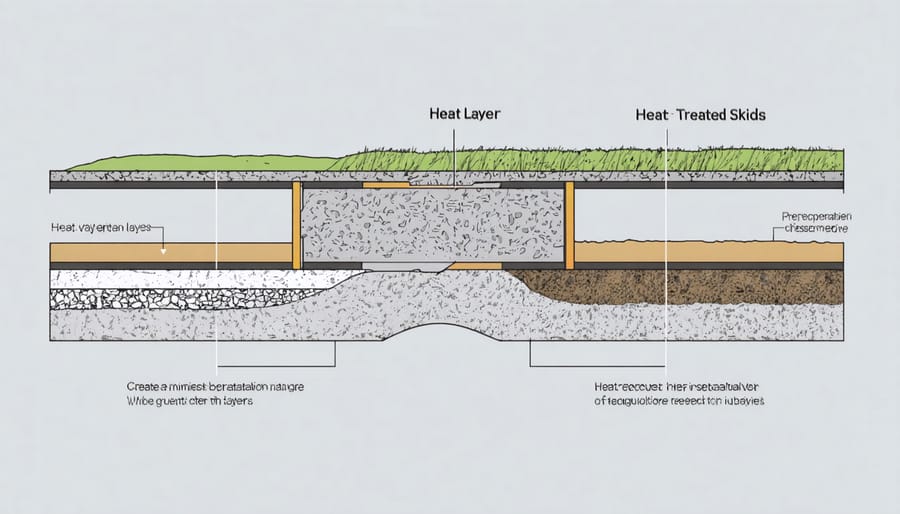

Ground Contact Considerations

\n\nProper ground preparation is crucial for the longevity of your heat-treated skids and the structure they support. Start by selecting a level area for your shed, removing any vegetation, rocks, or debris. The ground should be compacted and as even as possible to prevent future settling issues.\n\nFor optimal performance, place a layer of gravel or crushed stone at least 4 inches deep across the entire footprint of your shed. This foundation layer helps with drainage and prevents moisture from directly contacting the skids. Make sure to rake the gravel level and compact it thoroughly before placing your skids.\n\nConsider using concrete blocks or pier blocks beneath the skids at key support points. These blocks should be placed approximately every 4-6 feet along the length of each skid, ensuring they’re perfectly level with each other. This elevation helps protect the skids from ground moisture and improves airflow underneath your structure.\n\nIn areas with poor drainage or high moisture content, adding a vapor barrier between the ground and your skids can provide extra protection. Remember to check local building codes, as some areas require specific foundation preparations or minimum clearances from the ground.\n\nRegular inspection of the ground contact points is essential. Watch for signs of settling, erosion around the foundation, or water pooling near the skids. Address any issues promptly to maintain the stability and longevity of your structure.\n\n

\n

\n\n\n

Additional Protection Methods

\n\nWhile heat treatment provides excellent protection for your skids, implementing additional safeguards can significantly extend their lifespan. One of the most effective ways to protect against moisture damage is applying a high-quality wood sealer specifically designed for ground contact. This creates an extra barrier against moisture and insects.\n\nConsider installing a vapor barrier beneath your skids before placement. A heavy-duty polyethylene sheet acts as a moisture block between the ground and your skids, preventing ground moisture from seeping upward. Additionally, raising your skids slightly off the ground using concrete blocks or gravel beds improves airflow and reduces direct soil contact.\n\nRegular maintenance plays a crucial role in protection. Inspect your skids annually for signs of wear or damage, and reapply sealant as needed, typically every 2-3 years. Keep the area around your skids clear of vegetation and debris, as these can trap moisture and attract pests.\n\nFor areas with severe weather conditions, consider adding metal brackets or supports to reinforce the connection between skids and your shed floor. This not only provides additional structural support but also helps distribute weight more evenly, preventing premature wear on specific points of the skids.\n\n\n

Maintenance and Long-Term Care

\n\nProper maintenance of your heat-treated skids will significantly extend their lifespan and protect your shed investment. Start by conducting regular visual inspections every six months, checking for signs of moisture damage, wood rot, or pest infestations. Pay special attention to areas where the skids contact the ground, as these are most vulnerable to deterioration.\n\nKeep the area around your skids clean and free from debris, leaves, and vegetation. Plant growth can trap moisture against the wood and accelerate decay. Maintain proper drainage around your shed by ensuring the ground slopes away from the structure, preventing water from pooling near the skids.\n\nApply a water-resistant sealant to exposed wood surfaces every 2-3 years. This extra protection helps maintain the effectiveness of the heat treatment and provides additional moisture resistance. When selecting a sealant, choose one specifically designed for treated wood and outdoor use.\n\nIf you notice any damaged areas, address them promptly. Small cracks or splits can be filled with exterior-grade wood filler, while more serious damage may require partial replacement of affected sections. Keep the skids elevated using concrete blocks or gravel beds to minimize ground contact and improve air circulation.\n\nDuring seasonal changes, check that your shed remains level on the skids. Ground movement from freeze-thaw cycles can affect alignment. Use a level to check, and adjust support points as needed to maintain proper distribution of weight across all skids.\n\nRemember to keep records of your maintenance activities, including dates of inspections and any repairs made. This documentation helps track the condition of your skids over time and plan for future maintenance needs.\n\n\nHeat-treated skids offer an excellent foundation solution for your shed, combining durability, pest resistance, and environmental safety. By choosing these treated supports, you’re investing in a longer-lasting structure that will protect your belongings for years to come. Remember to always purchase ISPM 15 certified skids, ensure proper installation with adequate ground preparation, and maintain regular inspections of your foundation. Whether you’re building a new shed or upgrading an existing one, heat-treated skids provide the peace of mind that comes with knowing your structure rests on a solid, reliable foundation. With proper installation and maintenance, these skids will continue to protect your investment while keeping your storage space dry and stable through changing seasons and weather conditions.